No Products in the Cart

Plasma sputtering coating, a fascinating technique in materials science and engineering, involves the deposition of thin films of material onto a substrate through sputtering. This process is achieved by ejecting material from a "target" material to the "substrate" using a plasma.

Plasma sputtering coating is pivotal in industries that demand high precision and durability in thin film coatings, such as optics, where marumi is involved, the semiconductor industry for Integrated circuits (ICs) and microchips, Solar Panels, or Automobile and aerospace industries.

Japan is one of the country where leads this technology ahead of the world.

Plasma sputtering is a breakthrough technology used for applying coatings to lens filter surface.

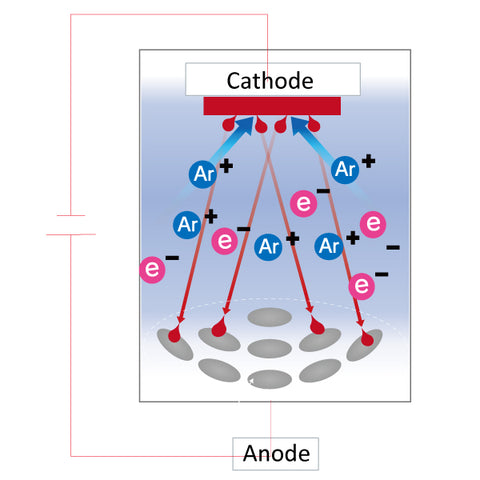

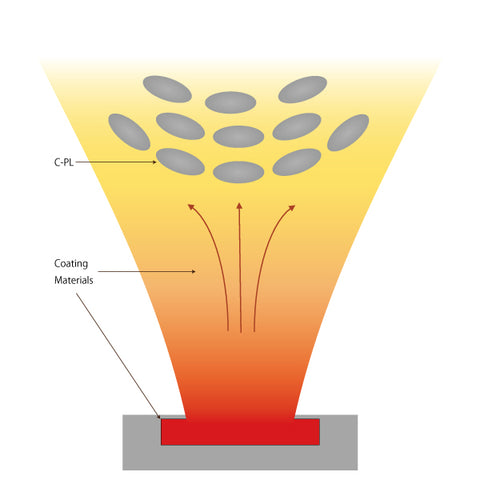

It involves using plasmaized argon gas to impinge on the coating material, depositing it in an orderly manner onto the filter surface.

What is Plasma?

Plasma is often referred to as the fourth state of matter, distinct from solid, liquid, and gas. It's essentially a cloud of charged particles, including electrons and ions, that exhibit collective behavior.

You can think of plasma as a very energized gas that has enough energy to free electrons from atoms, creating a soup of charged particles.

Sputtering Process:

In plasma sputtering, a target material (the source of the coating material) is bombarded with energetic particles from the plasma. When these particles hit the target, they knock atoms out of it. These ejected atoms then travel through the vacuum in the chamber and deposit on the substrate, forming a thin film.

Imagine playing a very microscopic game of billiards where the plasma particles are the cue ball, the target material's atoms are the billiard balls, and the substrate is the pocket. The goal is to shoot atoms into the substrate evenly.

This method contrasts with conventional vacuum evaporation, which relies on heating the coating material to high temperatures until it evaporates and adheres to the surface.

Plasma sputtering offers advantages such as no radiant heat damage to sensitive materials, enabling multi-layer coating over time, resulting in dense, hard, and lean coatings.